DAVI Engine Use Case (Use and strength)

High-magnification & high-precision, best for 3D appearance defect detection

- High-precision device for 5G communication

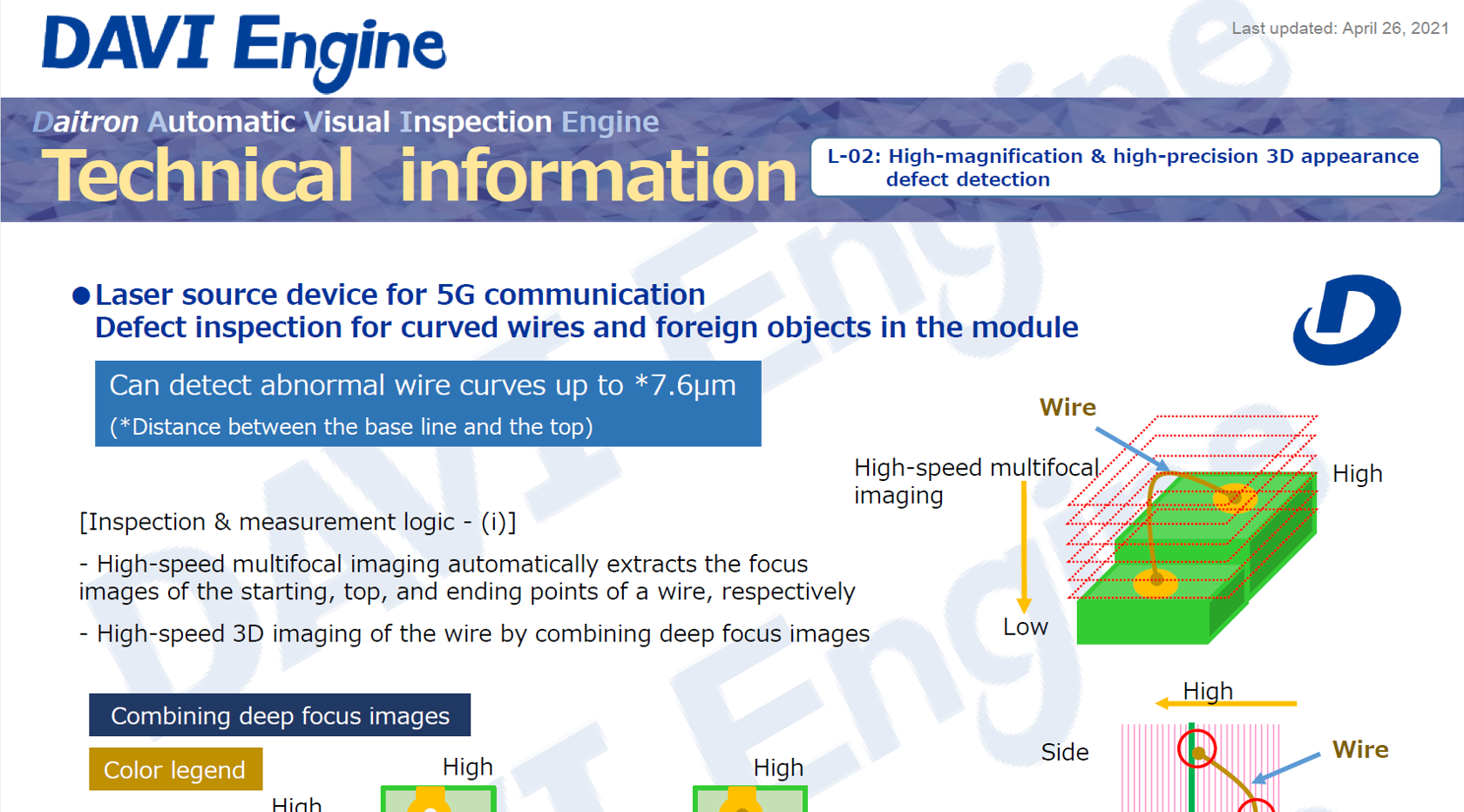

- Laser source for 5G communication device

Defect inspection for curved wires and foreign objects in the module

|

[Inspection & measurement logic] (1) Multifocal imaging using our original high-speed AF technology realizes 3D imaging by combining deep focus images of the starting, top, and ending points of a wire (2) Can detect wire curve defects by calculating the distance between the top and the base line connecting the starting and the ending points of a wire |

|

|

[Performance & capacity (example)] Can detect abnormal wire curves up to *7.6 μm (*Distance between the base line and the top) * May vary according to conditions. |

To the laser related glossary >

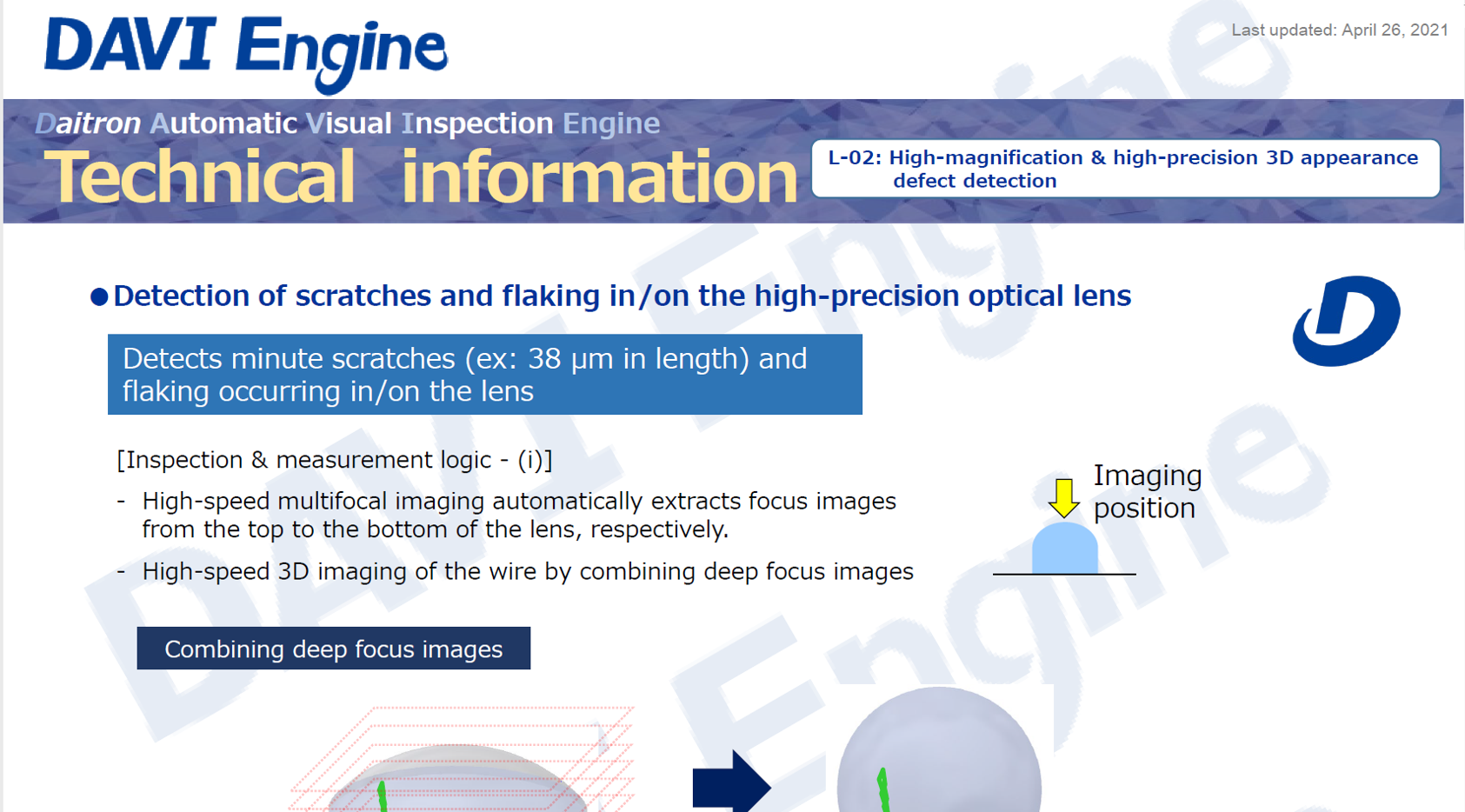

- High-precision optical lens

- Recognizes minute scratches, flaking, etc. in/on a lens

|

[Inspection & measurement logic] (1) Multifocal imaging using our original high-speed AF technology realizes 3D imaging by combining deep focus images from the top to the bottom of the lens (2) Detects defects in 3D images by our original hybrid image processing technology |

DAVI high-magnification & high-precision 3D appearance defect detection Lense_Check |

|

[Performance & capacity (example)] Can detect scratches of *33.77-μm-long in/on a lens) * May vary according to conditions. |

- High-precision 3D device

- Detects defects in shapes and foreign objects of 3D devices such as MEMS, which conventional AF is weak in

|

[Inspection & measurement logic] (1) Plot more than one focusing point in advance, and take a focus image at each of them (2) Detects defects of each surface by our original hybrid image processing technology |

- sample image |

|

[Performance & capacity (example)] Under construction * May vary according to conditions. |

- Complex shape medical device (proposal)

- Defect inspection for high-precision 3D meshed parts including vascular stents and high-precision DNA filters

|

[Inspection & measurement logic] (1) Plot more than one focusing point in advance, and take a focus image at each of them (2) Detects defects of each surface by our original hybrid image processing technology |

Source: General and Gastroenterological Surgery, Keio University School of Medicine Approval date: Oct 2, 2020 |

|

[Performance & capacity (example)] Can detect 3D shape anomalies on the micron level * May vary according to conditions. |

Allows both intuitive appearance determination and numerical determination

- Automatic inspection for scratches & dirt on clothing (proposal)

- Can automatically inspect dirt and frays on the texture (fiber patterns), which conventional rule-based image processors are weak in, only by defect labelling. Furthermore, classification according to the size of the defect is possible, too.

|

[Inspection & measurement logic] (1) Our original high-speed AF technology creates high-precision realistic images by connection processing that absorbs twists of the fabric and irregularities on the texture surface. |

- Defect detection procedure for nylon cloth |

|

[Performance & capacity (example)] * Please consult us with the required processing speed and inspection/part standards specified. * May vary according to conditions. |

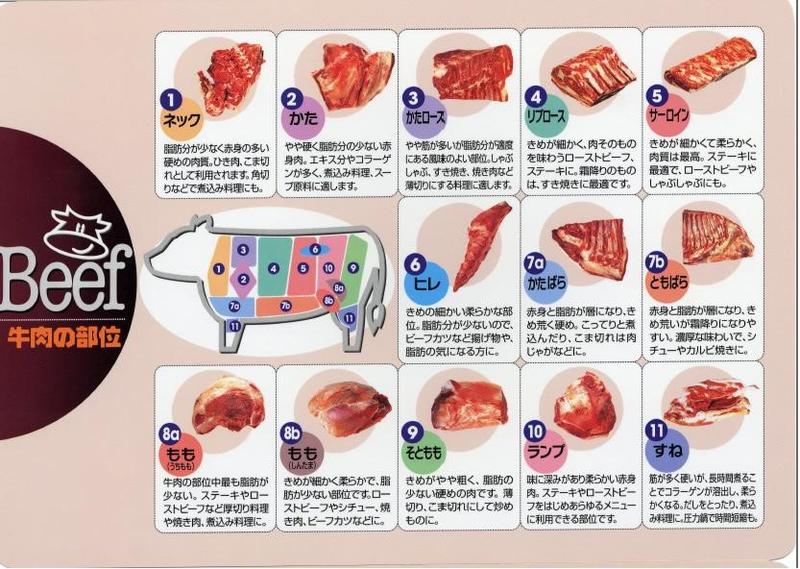

- Recognition of discontinuous patterns and shapes of meat and automatic determination of parts (proposal)

- Recognizes the shape and the texture (pattern) such as marbling of meat, which conventional rule-based image processing is weak in, by labeling processing. Allows automated inspections and further application to automatic classification of parts according to the density.

|

[Inspection & measurement logic] (1) Our original high-speed AF technology creates high-precision realistic images that absorb bump shapes of the surface of uneven lumps of meat. Allows examination of identification by color camera and internal observation by infrared camera. |

Source: Japan Meat Information Service Center Approval date: Oct 6, 2020 |

|

[Performance & capacity (example)] * Please consult us with the required processing speed and inspection/part standards specified. * May vary according to conditions. |