High-precision Visual Inspection System (6 sides) DAVI-6000

| Product Name | High-precision Visual Inspection System (6 sides) |

|---|---|

| Type | DAVI-6000 |

| Manufacturer | Daitron Co., Ltd. |

| Manufacturer logo |  |

Overview

This equipment can easily perform high-precision visual inspections such as dimension measurement and scratch inspections of semiconductor chips.

- High-speed deep focus measurement (multifocal imaging)

- High-precision measurement

- User-friendly software

- High-speed 6-face inspection and measurement

- Damageless handling mechanism

DAVI-Engine (Daitron Automatic Visual Inspection Engine) Introduction

"DAVI Engine" is a generic name of the Company's core technologies optimized on an advanced level by integrating AI (deep learning) with our D&P Company's know-how in high-precision optical imaging technologies & equipment system technologies.

With our application carrying this Engine, we provide solutions ranging from development machines to fully automatic inspection equipment, to contribute to releasing operators from visual inspection of products.

https://www.daitron.co.jp/en/products/solution_automatic_visual_inspection.html

Feature

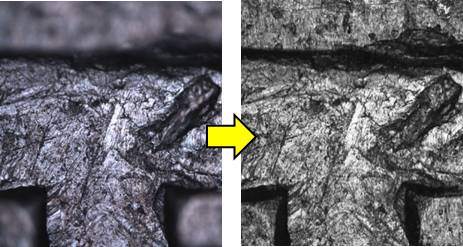

High-speed deep focus measurement (multifocal imaging)

Z-axis image combining processing enables deep focus images to be acquired at high speed with a high-magnification lens.

In addition, plane correction of inclined work is also possible.

In combining 20 images at 1-μm pitch: at 200 msec or below (the processing time will vary according to the number of images to be acquired)

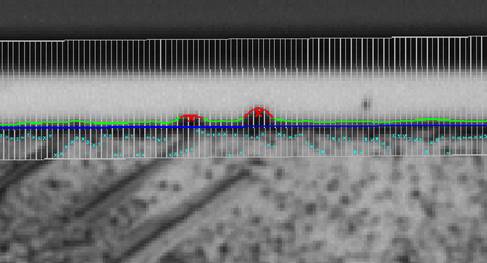

High-precision measurement

Can detect 1 μm or smaller edge defects and scratches. (at 20x)

Can also perform edge inspections for chips from and protrusions beyond an arbitrary line.

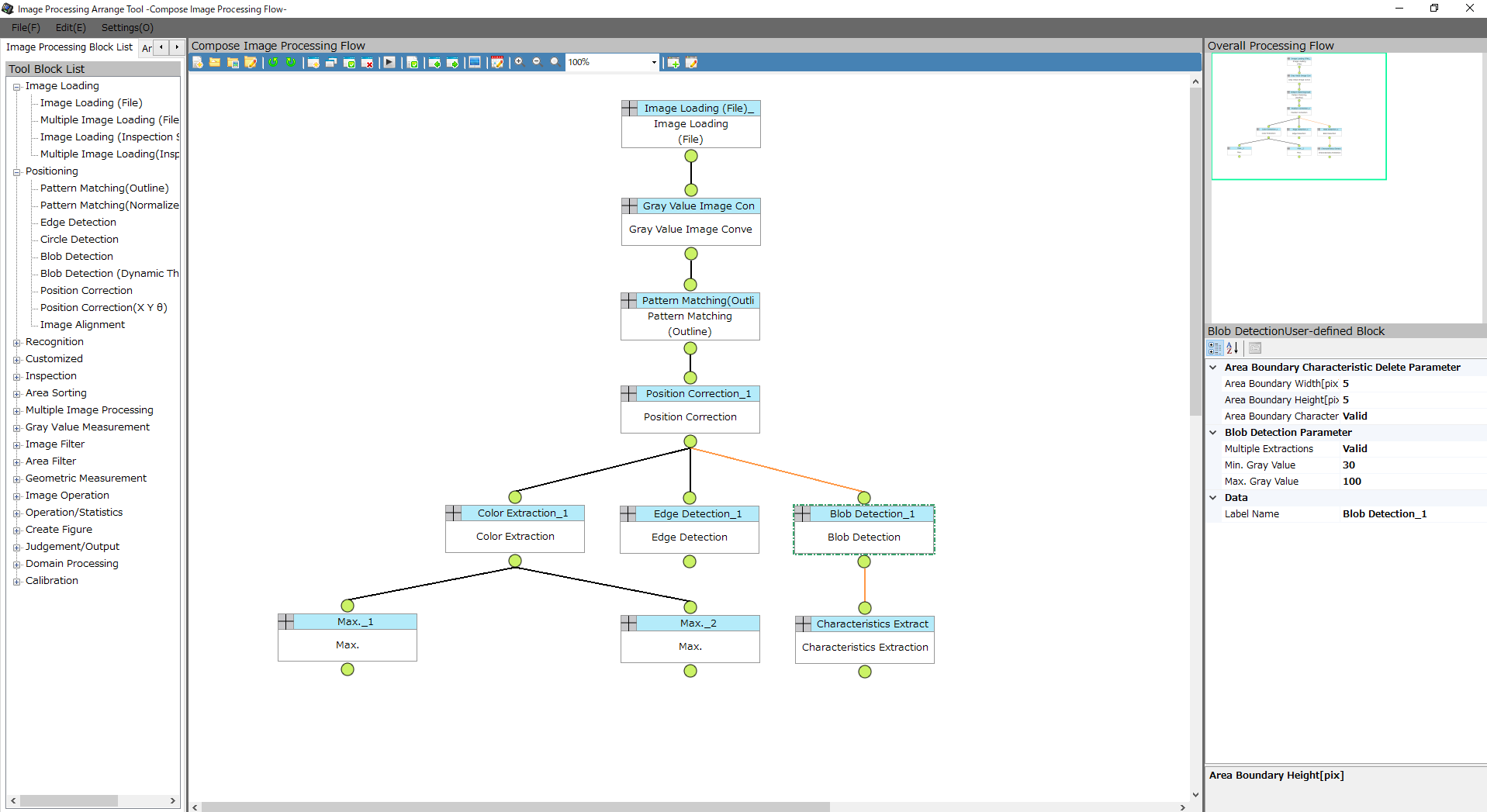

User-friendly software

HALCON-based image processing flows can be prepared by drag & paste.

High-performance HALCON libraries can be used without programming knowledge.

Free choice of hardware

Any equipment in the market such as cameras, lenses, and PCs can be used freely.

Real-time observation with line scan camera is also possible.

DAVI-6000 will enable you to make the best choice suitable to your specifications.

Main Specifications

Standard equipment specifications

| Equipment name | High-precision Visual Inspection System (6 sides) DAVI-6000 |

| Measurement stage |

6-face stage specifications (front-end face, right side/top surface, back-end face, left side face) The bottom face is measured at transport |

| Autofocus |

Z-axis (setting resolution 0.1 μm), high-speed autofocus (200 msec/20 images) * Will vary according to the exposure time |

| Object lens | 20x (optional) |

| Inspection resolution | Can inspect contamination and scratches of 1 μm, resolution 0.25 μm (at 20x) |

| Lighting | Coaxial vertical illumination (3-color high-intensity LED), ring lighting (3-color LED light: low angle) |

| Anti-vibration table | Active vacuum anti-vibration table |

| Control | PC (Windows base) |

| Function |

Automatic inspection sequence, variety registration, logging function (result data and image) Automatic stage cleaning, collet correction, consumables management |

| Image processing | HALCON-based original UI |

| Option | Deep learning (AI) function |

* The inspection stage stroke is customizable. We design to the inspection objects.

Standard inspection specifications

| Image combining | Z-axis image combining function at arbitrary pitch, tilt compensation combining |

| Two-position focus image combining, irregularity determination, plane combining | |

| Positioning | Pattern matching (boundary/normal correlation), edge position, pair edge, circle position, position correction |

| Identification | OCR, 2-dimensional code |

| Inspection | Trend edge, depth inspection, color extraction, blob, dynamic threshold, feature extraction, defect extraction |

| Measurement | Focus image acquisition, various dimension measurement tools |

| Filter |

Gray conversion, color space conversion, contrast conversion, gray value distribution measurement, Average gray value distribution measurement |

| Dilation/erosion filter, opening/ending filter | |

| Bottom hat, top hat, highpass, averaging, median, smoothing | |

| Laplacian filter, edge emphasis, contrast emphasis, binarization, inversion | |

| Gray value scaling, clipping, gray value distance | |

| Light density, threshold range | |

| Image computation | Various computing |

| Statistics | Maximum, minimum, mean, standard deviation |

| Output | Numeric output, calibration output |

| Drawing creation | Point creation, line creation, circle creation |

* Inspection tools other than the above will be prepared according to the inspection contents.

currently these products does not comply with US/EU electrical safety standards. Any customer who may require UL, CE, etc. please let Daitron know.