DAVI Engine

Daitron Automatic Visual Inspection Engine

Daitron Automatic Visual Inspection Engine

"DAVI Engine" is a generic name of the Company's core technologies optimized on an advanced level by integrating AI (deep learning) with our D&P Company's know-how in high-precision optical imaging technologies & equipment system technologies. With our application carrying this Engine, we provide solutions ranging from development machines to fully automatic inspection equipment, to contribute to releasing operators from visual inspection of products.

Total automatization solution for visual inspection

Our core technology Engine provides total automatization (equipment introduction) solution for visual inspection!

From product development and productivity improvement to resolution of worker shortage

Provides a technology quite similar to emulation visual inspection!

Pursuing a high level of reproducibility at inspection sites

| Solve the shortage of visual inspectors! Prevent appearance defective items from flowing out! | |

| - Guarantee of inspection reproducibility | ±2 micron or more * |

| - Quickly with manpower reduced |

Reduces time up to completion of automation start to 1/2 or less (compared to that of conventional Company products) * Ensured traceability |

| - Versatility | Easy response to multiple variety change with AI (deep learning) function |

*May vary according to conditions

| Example of Engine loaded application | |

| Standalone DAVI-1200 | Fully automatic inspection equipment DAVI-6000 |

|

|

Use and strength

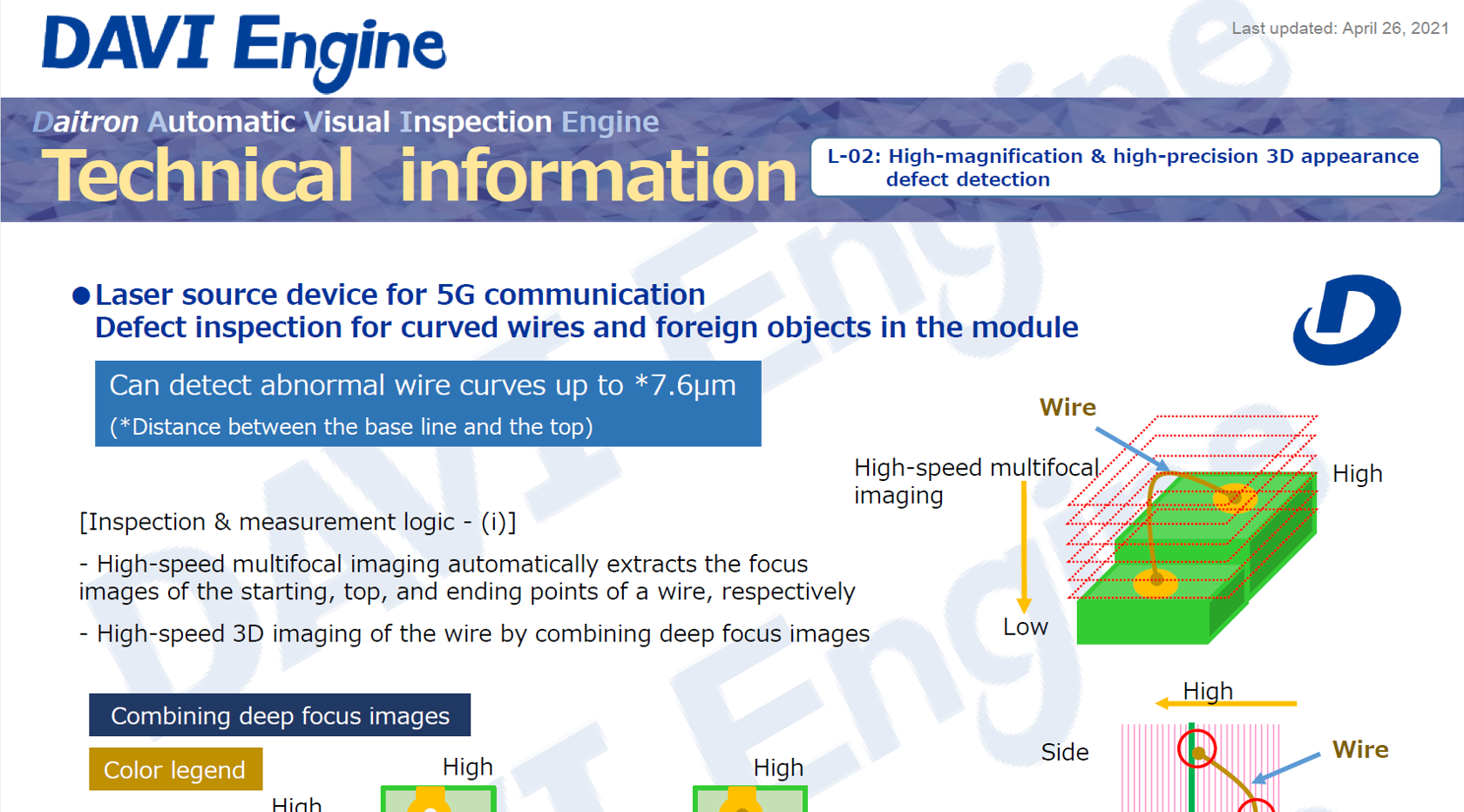

| 1 | High-magnification & high-precision, best for 3D appearance defect detection > |

High-precision device for 5G communication High-precision optical lens High-precision 3D device Complex shape medical device |

| 2 |

Allows both intuitive appearance determination and numerical determination > Integration of AI (deep learning) learning function and rule-based numerical control |

Defect in fiber/texture Can inspect fuzzy shapes Determines discontinuous patterns of meat, etc. |

| 3 | Pre-introduction consulting by [D-LABO Kanazawa] is possible > |

Remote sample evaluation at customer's site is possible Prior evaluation with actual machines at D-LABO Kanazawa is possible Remote consultation after introduction is possible |

Function and characteristics

| Fastest high-precision inspection [optimized as a system] | ||

| 1 |

- Ideal imaging |

|

| 2 | - Will meet your requests from standalones to high-speed multi-processors. - Integrated control of all equipment by original software development. Will provide dynamic inspection reliability and stability required for fully automatic equipment - Supports higher-level communications networks, and allows data linking with preceding and subsequent equipment |

|

| 3 |

AI (deep learning) × Rule base |

- Combines the best of various image processing methods used in the industry! - Uncompressed images directly to image processing |

| 4 |

Ultimate automatic inspection setting editor |

- Drag & Drop GUI type image processing library arrangement tool! - Even parameter knowledge for image processing, not to mention programming knowledge, is unnecessary - A good selection of image processing libraries, which are implementable in DAVI Editor. |

| 5 |

(DAVI Emulator System) |

- Inspection condition setting is sharable between standalones and full automatic machines (1) Will greatly reduce time for establishing an automatic inspection line and variety change! (2) The setting recommended in [D-LABO Kanazawa] can be tried immediately at your site! |

| 6 | Precise motion control technology > |

- Precision stage technology for high-magnification inspections. Optimal control by total design from parts/assembly accuracy to various alignment controls and anti-vibration design |

| 7 |

[Inspection result review & Analysis function] (Inspection result value data output) |

- The built-in mechanism allows the inspection data visualization and inspection result analyses (future distribution map & graph display, viewer (visualizing software)) |

| 8 |

[D-LABO Kanazawa] Consultation > [Sample evaluation system] |

- Consultation and proposal for automation of customers' appearance inspection with enhanced evaluation equipment and systems |