High-precision Visual Inspection System DAVI-1200

| Product Name | High-precision Visual Inspection System |

|---|---|

| Type | DAVI-1200 |

| Manufacturer | Daitron Co., Ltd. |

| Manufacturer logo |  |

Overview

This equipment can easily perform high-precision visual inspections such as dimension measurement and scratch inspections of semiconductor chips.

- High-speed deep focus measurement (multifocal imaging)

- High-precision measurement

- User-friendly software

Feature

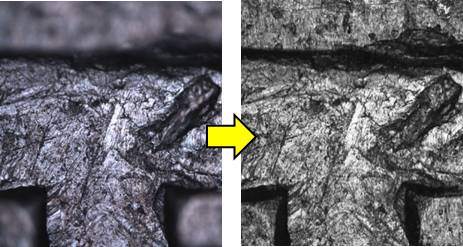

High-speed deep focus measurement (multifocal imaging)

Z-axis image combining processing enables deep focus images to be acquired at high speed with a high-magnification lens.

In addition, plane correction of inclined work is also possible.

In combining 20 images at 1-μm pitch: at 200 msec or below (the processing time will vary according to the number of images to be acquired)

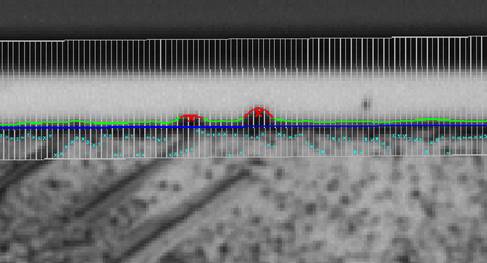

High-precision measurement

Can detect 1 μm or smaller edge defects and scratches. (at 20x)

Can also perform edge inspections for chips from and protrusions beyond an arbitrary line.

User-friendly software

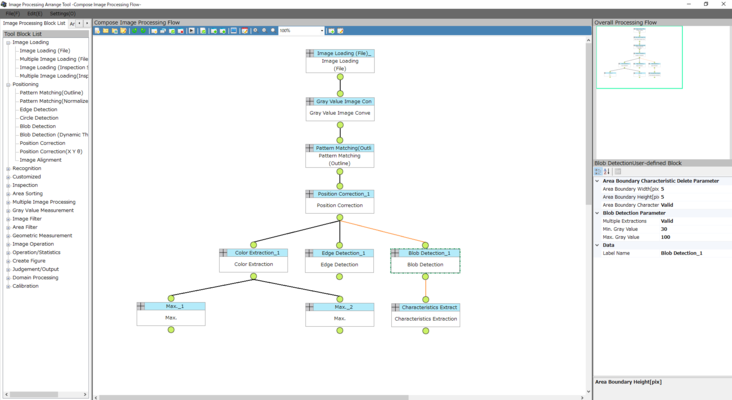

HALCON-based image processing flows can be prepared by drag & paste.

High-performance HALCON libraries can be used without programming knowledge.

Free choice of hardware

Any equipment in the market such as cameras, lenses, and PCs can be used freely.

Real-time observation with line scan camera is also possible.

DAVI-1200 will enable you to make the best choice suitable to your specifications.

Main Specifications

Standard equipment specifications

| Equipment name | High-precision Visual Inspection System DAVI-1200 |

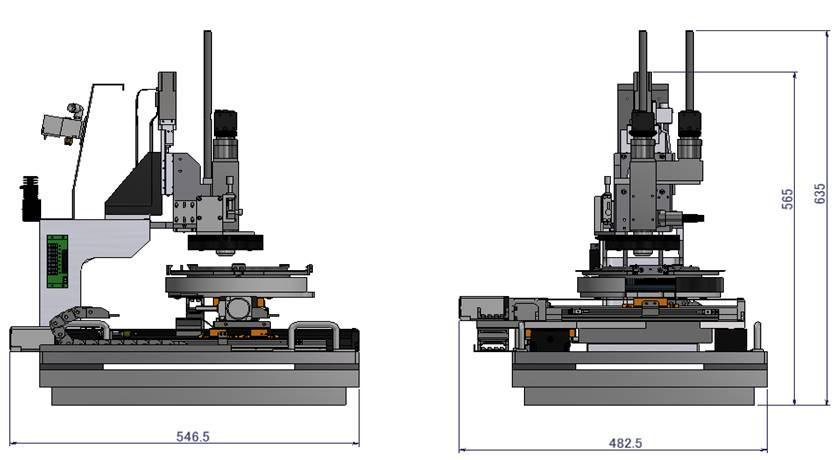

| Measurement stage | X,Y:□200 mm area θ-axis ±15° |

| Autofocus |

Z-axis (setting resolution 0.1 μm), high-speed autofocus (200 msec/20 images) * Will vary according to the exposure time |

| Object lens | 20x (optional) |

| Inspection resolution | Can inspect contamination and scratches of 1 μm, resolution 0.25 μm (at 20x) |

| Lighting | Coaxial vertical illumination (3-color high-intensity LED), ring lighting (3-color LED light: low angle) |

| Anti-vibration table | Passive vacuum anti-vibration table |

| Control | PC (Windows base) |

| Function | Automatic inspection sequence, variety registration, logging function (result data and image) |

| Image processing | HALCON-based original UI |

| Option | Deep learning (AI) function, side angle observation camera |

* The inspection stage stroke is customizable. We design to the inspection objects.

Standard inspection specifications

| Image combining | Z-axis image combining function at arbitrary pitch, tilt compensation combining |

| Two-position focus image combining, irregularity determination, plane combining | |

| Positioning | Pattern matching (boundary/normal correlation), edge position, pair edge, circle position, position correction |

| Identification | OCR, 2-dimensional code |

| Inspection | Trend edge, depth inspection, color extraction, blob, dynamic threshold, feature extraction, defect extraction |

| Measurement | Focus image acquisition, various dimension measurement tools |

| Filter |

Gray conversion, color space conversion, contrast conversion, gray value distribution measurement, Average gray value distribution measurement |

| Dilation/erosion filter, opening/ending filter | |

| Bottom hat, top hat, highpass, averaging, median, smoothing | |

| Laplacian filter, edge emphasis, contrast emphasis, binarization, inversion | |

| Gray value scaling, clipping, gray value distance | |

| Light density, threshold range | |

| Image computation | Various computing |

| Statistics | Maximum, minimum, mean, standard deviation |

| Output | Numeric output, calibration output |

| Drawing creation | Point creation, line creation, circle creation |

* Inspection tools other than the above will be prepared according to the inspection contents.

Currently these products does not comply with US/EU electrical safety standards. Any customer who may require UL, CE, etc. please let Daitron know.